Classic International

JOINT VENTURE

CONTELEC Inc.

Electrical & Instrumentation Contractor

Consolidated Technical Statement Project Execution Experience

Purpose of Document

This consolidated technical statement has been prepared by CONTELEC INC to support scope alignment with the requirements outlined in the technical proposal for the Sphinx Furnace Electrification Project in Saudi Arabia, currently under development by Siemens. The selected experience highlights relevant execution capabilities consistent with the engineering, installation, QA/QC, and operational expectations defined in the proposal—particularly in relation to substation works, cable infrastructure, OEM integration, and safety governance.

Project 1: Refinería de Esmeraldas Energy Recovery Program

Client: Petroecuador – EPP

Prime Contractor: MMR Group

Executed by: ROALNE INC. (now CONTELEC INC)

Location: Esmeraldas, Ecuador

Period: 07/2015 – 02/2016

Scope of Work Executed

CONTELEC Inc., operating under its former name ROALNE Inc., performed specialized highvoltage works in the energy recovery program of the Refinería Esmeraldas. The scope included:

• Installation of power cables (132 kV, 69 kV, 34.5 kV) in both underground and overhead configurations

• Construction of reinforced duct banks and tray systems for MV distribution

• Dry-type cable terminations and connections to transformer and switchgear systems

• Integration of Siemens 69 kV / 34.5 kV power transformers and associated control/protection systems

• Electrical assembly within ABB ELK-04 GIS units (feeders Q01 to Q04, disconnectors Q06 to Q09

• Connection of auxiliary panels, medium-voltage switchgear, and control equipment

• Full involvement in energization, coordination of relay protection systems, and support to startup protocols

Testing, Commissioning & QA/QC Involvement

All installations were tested using certified protocols:

• Very Low Frequency (VLF) testing at 0.1 Hz

o Voltage applied: 105 kV on 69 kV cable runs

o Duration: ≥ 60 minutes per circuit

o Standards: IEC 60502-2, IEEE 400.2

o Measurements: Tan Delta, leakage current, capacitive profile

• GIS mechanical validation at nominal and variable voltages

o Motor current, operation time, SF₆ pressure and insulation integrity

• Protection system simulation and continuity testing

• All FAT/SAT procedures documented and signed by ABB and client representatives

Additionally, a dedicated QA/QC team from ROALNE Inc. supported procedure validation alongside representatives of ABB, Siemens, and Petroecuador. The team participated in inspection tracking, measurement verification, and multi-party documentation across test protocols.

Substation Custody & Safety Coordination

During execution, ROALNE INC. maintained custodial responsibility for the substation, including:

• Enforcement of Lock-Out/Tag-Out (LOTO) procedures across contractors

• Issuance and control of Permit-to-Work systems, confined space access, and area isolation

• Interface with client safety staff to ensure compliant execution and access control

Results & Relevance

• All components energized and handed over without technical deviation

• VLF and GIS testing validated and archived

• Siemens and ABB systems operational and conforming to IEC standards

• Zero incident record during construction, testing, or startup.

• QA/QC participation confirmed CONTELEC Inc.’s technical competency and reliability

• Experience directly supports HV/MV project scopes, OEM integration, safety

Project 2: El Furrial High Pressure Gas Injection Facility

Client: Wilpro S.A.

Prime Contractor: MMR Group

Executed by: ROALNE C.A. (now CONTELEC INC)

Location: El Furrial, Venezuela

Period: February – October 2000

Scope of Work Executed

ROALNE C.A.. was contracted by MMR Group to execute electrical infrastructure works for the High-Pressureon Plant at El Furrial. The scope included:

• Installation of a three-phase 1250 MCM cable circuit covering 2.3 km through reinforced concrete duct banks

• Cable grounding, pulling, positioning, and sectional validation

• Deployment of a 69 kV / 13.8 kV substation, featuring:

o Five AIS bays (Air-Insulated Switchgear) from General Electric

o Full relay panel integration, busbar connections, and MV switchgear terminations

• MCC (Motor Control Center) installation with Square D units by Schneider Electric, including:

o Control wiring, auxiliary cabling, dressing, and labeling

o Panel interconnections and commissioning

• Execution of low- and medium-voltage wiring associated with MCCs, switchgear compartments, and support panels

• Full participation in equipment inspections and system handover protocols

During the post-installation phase, technical personnel from C.A. were assigned by MMR Group to Wilpro S.A. for operational support and preventive maintenance across the facility. This arrangement spanned two years and involved system supervision, inspection coordination, and technical oversight — reinforcing the reliability and sustained performance of the infrastructure delivered.

Testing & Commissioning Protocols

• Double-voltage testing using OMICRON CPC equipment

o Evaluated insulation resistance, capacitance, and power factor

o Applied across HV cable segments and substation apparatus

• Functional checks for MCC and switchgear panels

• Relay protection testing and grounding verification

• Test witnessing with Wilpro and GE representatives

• Completion of punch list and full operational release

Safety & Documentation Oversight

• Lock-out/tag-out supervision during installation and energization

• Permit control for electrical works across subcontractors

• Technical participation in QA/QC activities during client and OEM inspections

Results & Relevance

• Cable circuits successfully installed, tested, and energized

• Substation and MCC systems fully functional and commissioned

• Client validation confirmed under multi-party inspection

• Technical presence extended beyond construction into long-term operational support

• Experience proves CONTELEC Inc.’s capability in long-distance HV cabling, AIS/MCC integration, QA/QC compliance, and client collaboration

In addition to the documented HV/MV scopes presented above, CONTELEC Inc.(formerly ROALNE Inc.) holds a portfolio of nearly 30 years of proven execution, including numerous low-voltage infrastructure projects with similar service profiles. These works have encompassed panel assembly, MCC installations, cable routing, Control circuit configuration, and testing protocols aligned with industrial requirements. While not detailed herein, this broader track record confirms the company’s enduring commitment to technical quality and regulatory compliance across voltage classes and project environments.

Electrical, instrumentation and commissioning contractor

Contelec Inc. is a company registered in USA as a Subsidiary of general contractor Conteca Inc. to serve the international market more efficiently by

having a shorter response time.

Contelec Inc. has already executed projects in Colombia, Mexico, Ecuador, Bolivia, and Venezuela, with a presence of more than 25 years in the industry. These past projects have allowed us to build a work team with extensive experience in various disciplines and ready to face the challenges wherever

the needs of our clients take us

On a conventional or state-of-the-art project, Contelec Inc. will achieve the goals set by the client

Our commitment:

To add value by providing the highest level of service and quality, as well as completing projects efficiently and safely.

We rely on four pillars:

1. Our people

They are the foundation of our organization to whom we provide the support and motivation with the aim to share our commitment to quality and customer satisfaction.

2. Safety, Hygiene and Environment

It is an integral part of our corporate culture. More than a regulation, it is an investment. Our board of directors is committed to assuming a diligent role in providing the economic, human, and technological resources that lead to the success of SHA management.

3. Assurance and Quality Control

Contelec Inc. counts on a proven Quality Management System, which we constantly improve over time to provide quality and profitable services on a competitive basis.

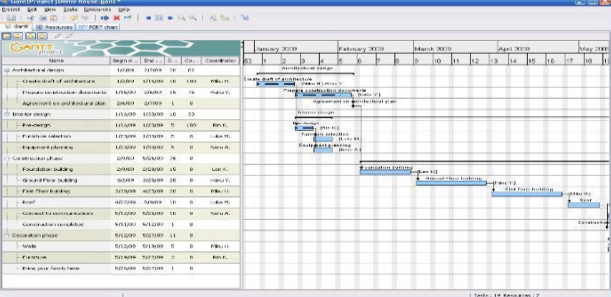

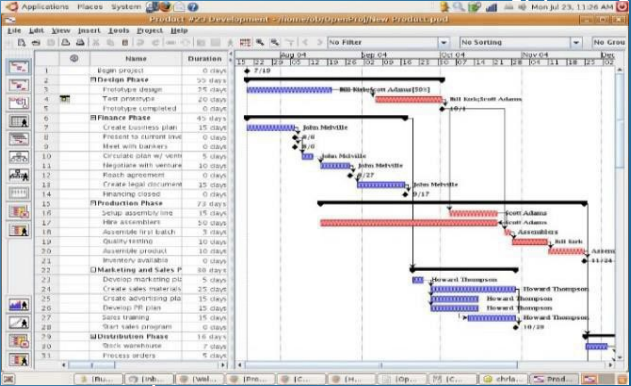

4. Project Controls and Technology

We operate with the conviction that only good documentation control with efficient and objective scheduling makes possible the completion of a project on timely matter and within budgeted cost.

1.OUR PEOPLE

Contelec inc. As an international Company manages multicultural diversity in our staff. This diversity is already part of our organizational idiosyncrasy.

Managing culture shock allows us to meet the challenges assumed by integrating and interacting with multidisciplinary and multicultural teams with less time impact on familiarization with the assigned task.

Some of our projects include the supply of personnel and technicians of a certain profile and specific positions in managerial, supervisory and technical support.

Contelec inc. achieves the competence and awareness control requested by the ISO 9001 2015 standard by considering the following topics:

• Training Plan and Objectives

• Induction Training

• Training Needs Assessment

• Development of Skills

• Management System Training

• On-the-Job Training

• Performance Review

• Training Evaluation

• Review

• Keeping written Forms & Records

If necessary, Contelec inc. can use the services of PAYCHEX to carry out the Certified Training Evaluation Plan through the HR Module.

2.Safety, Hygiene and Environment

Our SHA Management System designs the processes and programs of SHA policy and implements them with a guideline of zero accidents.

The Safety policy is based on education and training, defining responsibilities in order to ensure compliance of the regulatory requirements and contractual obligations to obtain our ZERO ACCIDENTS goal. Management and staff are

committed to the continuous improvement of policies and procedures for the protection of our employees costumers, visitors, Project assets, the community, and the Project enviroment.

Contelec inc. to fulfill its commitment to ISO 45001:2018 occupational health and safety management systems, if necessary, can use the services of PAYCHEX to obtain each specific Safety Program and the training required for personnel.

3.Assurance and quality control

Our quality Management System is adapted to the activities, practices, tasks, and protocols developed in our projects. Our personnel are committed to respect, ensure, practice, and adapt to the specifications, standards (NEC, NETA), drawings, and codes required to comply with the client´s request.

Contelec in., to fulfill its commitment to the ISO 9001 1015 Standard has implemented its own Quality Management System. In addition, if necessary, it supports its activities related to procurement, reception, release, storage, and installation of materials and equipment with the specialized service provided by the Deltek Vantagepoint platform.

4. Project Control

- We maintain a wide range of procedures and reports to manage the project with a full

traceability. - The reports are adapted to the size of the project and its duration.

- We generate reports, trends and forecasts for delivery: daily, weekly and/or monthly.

- Total adaptability to the report formats and specific reports of our clients.

- We have Computerized Maintenance Management Software (CMMS) available for reliability and maintenance contracts.

- We provide our clients with “real” time project status.

TECHNOLOGY

Contelec inc. optimizes its human resources through the use of collaborative tools, such as:

- Team

- SharePoint

- Chat

- Outlook

The use of these tools within the Office 365 platform not only enables our personnel located in different locations to meet daily in virtual rooms to monitor all phases of the project and seek fasttrack solutions to problems that arise during its execution, but also allows us to maintain a high degree of security for our administrative, operational, and support systems, as well as for our clients documented information.

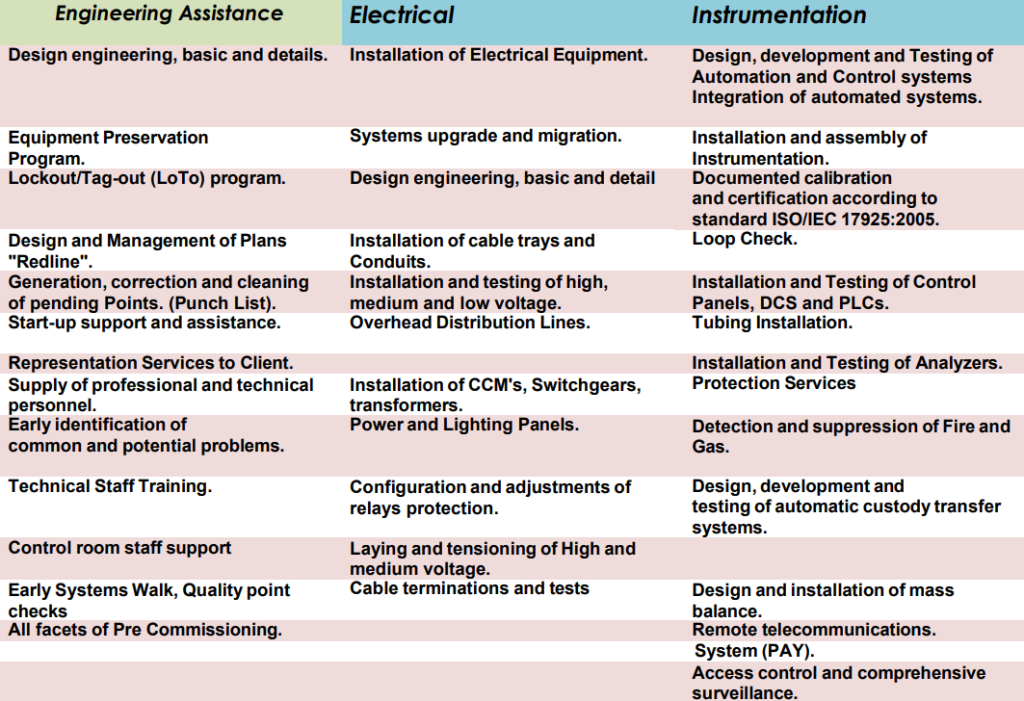

Our services 1

At Contelec Inc., we have hard working and highly experienced staff with the know-how in electrical and instrumentation systems that guarantees the execution of the distinct Procurement phases of the project and Construction from Engineering, (EPC), including

Commissioning and start- up, to maintenance and operation of the installation.

Engineering: we provide studies and engineering services from the feasibility of the project to the development of Conceptual, Basic and Detailed Engineering for instrumentation and electrical disciplines.

Procurement: Our geographical location allows us to manage and oversee the procurement and logistics of the assigned projects within the required deadlines.

Construction: Being a specialized E, I & C contractor allows us to develop and enhance skills and knowledge that are unique of the Electrical, Instrumentation & Commissioning disciplines seen in today’s modern facilities.

Our services 2

Commissioning: Contelec Inc. counts on specialized teams with specific profiles in electrical testing, loop checking, preCommissioning, Commissioning and Start-up. This team ensures our clients the transition, without inconveniences, from the construction of the facilities to their operation and reliability. We

always advise early presence of Pre-Commissioning until Commissioning.

Maintenance: our support can cover maintenance and operation phase of the facility, supplying specialized personnel and working together with the client in the development of maintainability and operational reliability policies. These last two services are available even for projects executed by third parties through hiring of specialized manpower or through contracts for defined scopes.

Knowing the required profile and/or the scope of work, we guarantee the suitability of the manpower that the project needs.

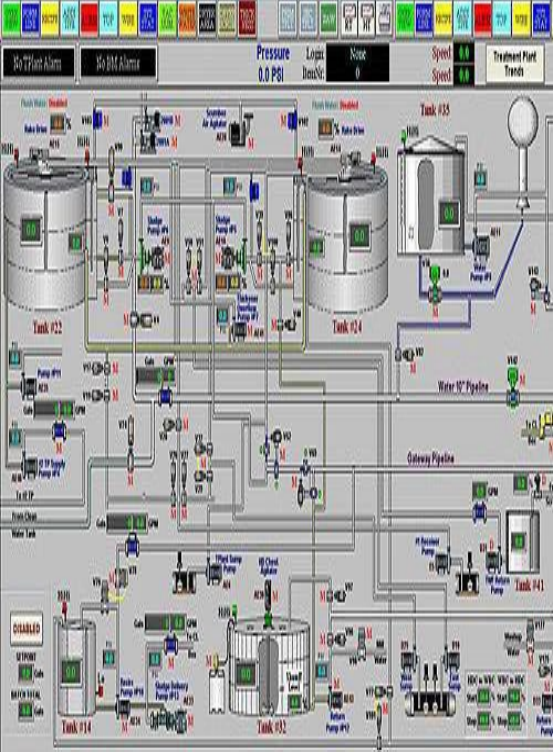

Other Specialized services

Automation Services: Our engineers at Contel ec Inc. have the skill and knowledge for the development and implementation of Automated Information Systems. PLC’s, networks, equipment, and computers can be implemented according to the protocols and standards specified by the customer

We can also provide support to integrate different equipment, protocols, and interfaces, making the systems more effective, usable, and intuitive.

Other Specialized services

Protection Systems: We specialize in navigation

systems, gas and fire detection, fire products, PAGA systems.

Our certified technicians are qualified to install, repair and service most equipment brands on the market and, thereby, provide solutions to your requirements.

Other Specialized Services 2:

Fiscal and reference flows for measuring production flows, mass balance, tank inventory, sale, or purchase of products for both liquids and gases, require qualified personnel who will design and build what suits your facilities.

Lease and Custody Transfer System (LACTS). Our team has the skills to design, manufacture, install, test and commissioning Transfer Systems and Lease Automatic Custody.

From design and calculations to determine what applies to your lease, up to the start-up and support of your operation for days, through fabrication of the facility that may include skids, pipes, cabinets, and panels, among others. Whatever the operation needs.

Table of Services We Provided

Our Market

For 25 years, we have served the Oil, Gas, Petrochemical, chemical, thermal generation, and manufacturing industries, both in Construction and in

Maintenance.

This combines the use of cutting-edge technology with our unwavering commitment with safety, quality and customer satisfaction.

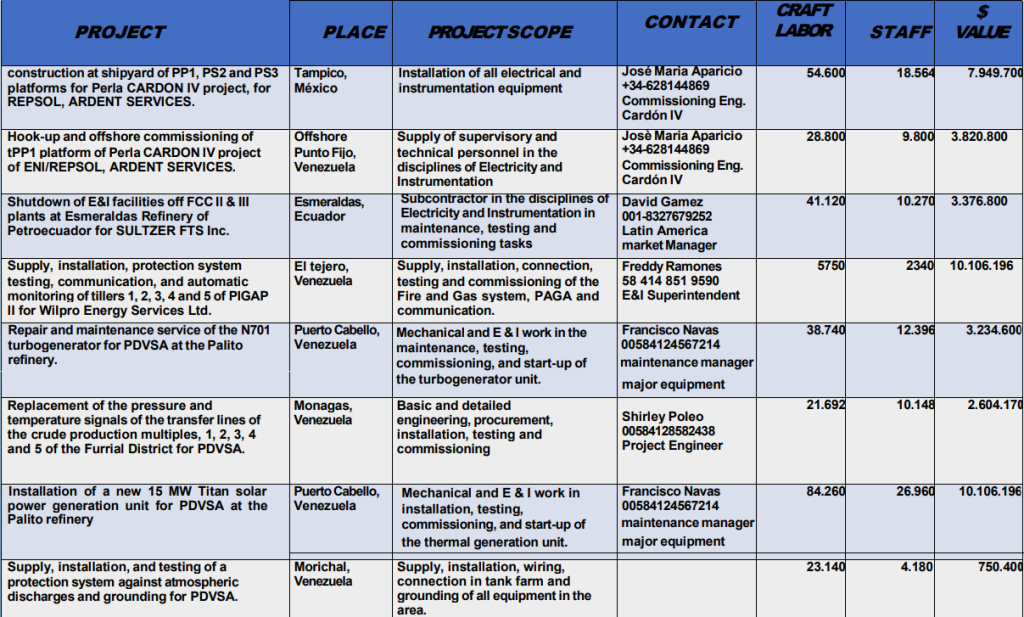

Our Experience

Our experience includes modular systems built in fabrication yards and transported offshore for installation, testing and commissioning.

From gas turbines and fossil fuel-fired plants, we have the know-how, the manpower and the resources to get the job done right

Special systems, unique facilities and severe weather are our forte and we will go wherever the job will take us.

We take each project as an opportunity to expand our experience and strengthen our commitment to excellence.

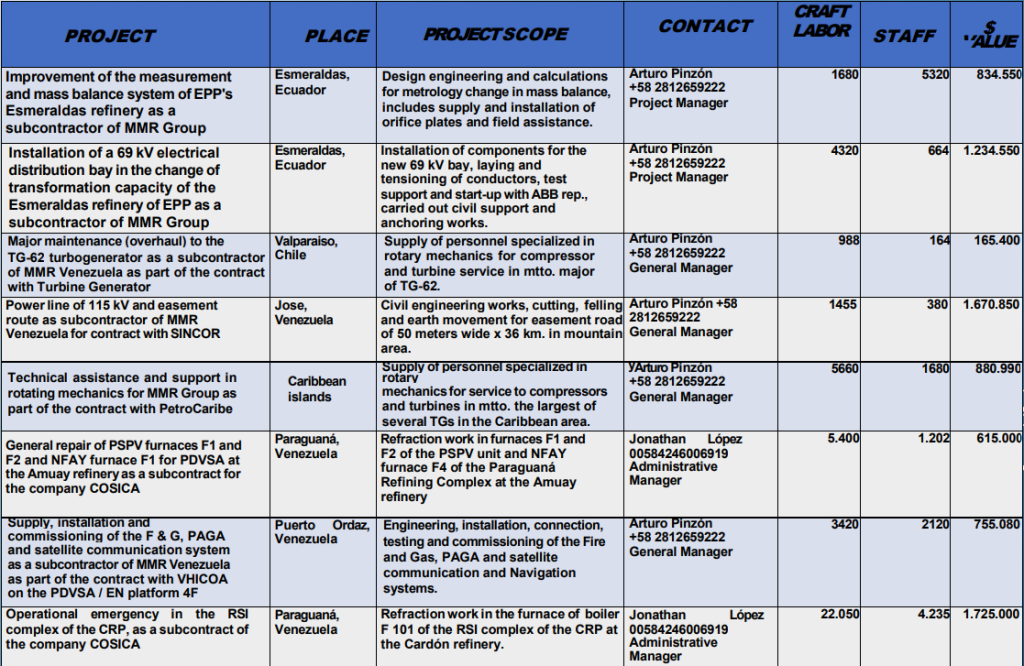

Notable Projects carried out by Contelec Inc.

OUR CLIENTS

We have always regarded partners as one of the most important aspect of our business.

ASSISTED COUNTRIES

Keeping in step with times ans scope with the ever increasing demand of the changes in the Industrial Sector, we have contributed our own milestones during the period.

Useful Links

Office Address

Contelec Inc.

10450 NW 33rd St Suite 305 Miami – Florida – 33172 USA

Call us on

Dante Osteicoechea.

Managing Consultant

+1 (786) 393 1554

Joaquin Silveira

General Manager

+1 507 6423 4282

David Roberty

General Manager

+1 504 450 0084

©2026. Classic International Contracting Company. All Rights Reserved.